Industrial Data Management Systems: The Key to the Success in Manufacturing

In fact, older methods of data operating hamper the working process. The data performed by the manufacturing facilities increases rapidly and must be processed, sorted, and saved in the correct order. All this demands time and human effort.

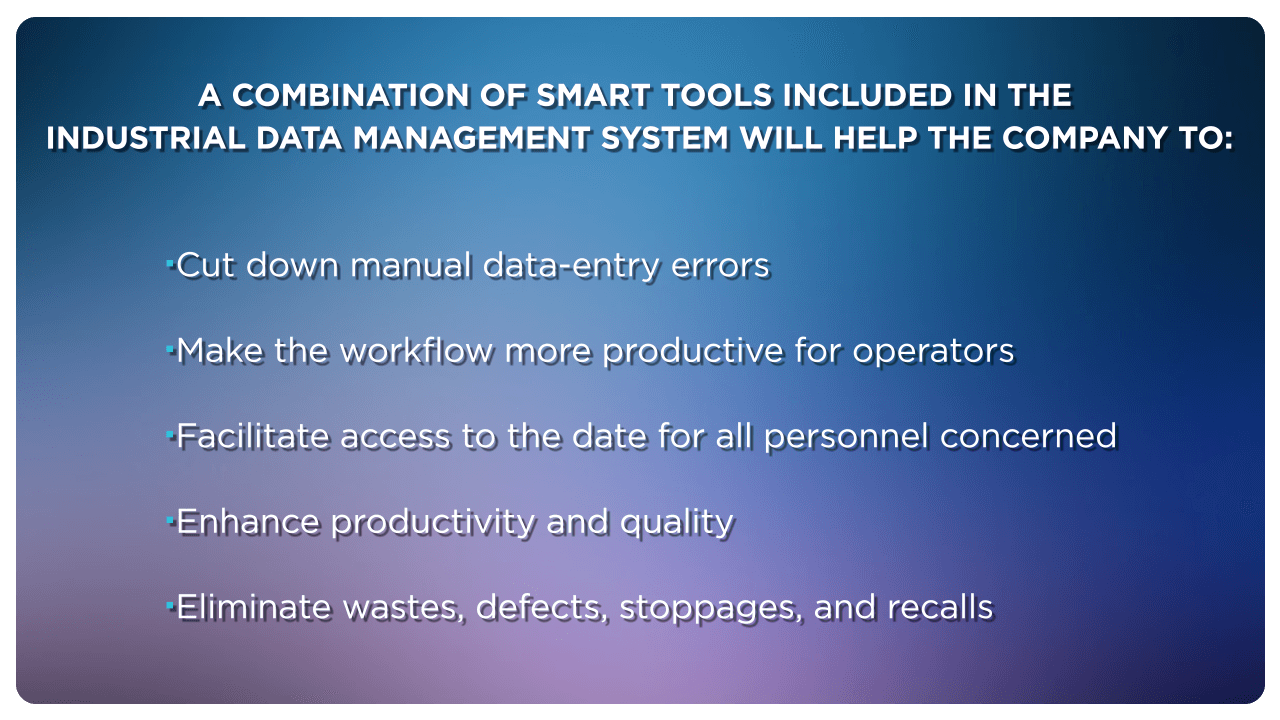

To meet goals and maintain the workflow, an enterprise needs to implement more automation into data operations. Automation benefits the industrial company by:

- eliminating downtime;

- making information complete and readily available;

- boosting productivity;

- cutting down on waste;

- minimizing maintenance costs; and

- increasing

All these goals are achievable by implementing modern industrial data management systems. An enterprise aiming for growth and a high ROI should replace old data processing methods with modern systems.

A data management system is the key tool to boost efficiency, reduce costs and raise the ROI of the company.

In this article, we will explore how an industrial data management system can take an enterprise to a new level. We will cover:

- The Challenges and Solutions in Manufacturing

- Industrial Data Management Systems: Importance and Key Features

- The Four Best Data Management Software Solutions in 2022

- How Long Does It Take to Build and Implement a DMS System?

The Challenges and Solutions in Manufacturing

Right now, the main problem enterprises face is the slowdown in their regular processes.

The volume of data is growing throughout the routine operations of manufacturing. As a result, there is a lack of tools to optimize and use the data.

Companies only realize a small part of the potential of the produced data. This issue especially concerns enterprises with automated manufacturing processes, producing large amounts of data every day. Collecting and processing an ocean of information is a real challenge.

The old style of working and implementing databases for data management is no longer effective. As a result, enterprises may lose time and money on useless inputs that interfere with and decrease the productivity of the whole system.

The challenges manufacturers face are as follows.

Challenge I: A Lack of Integrated Data Kept Real-Time in One Database

The data produced during the working process is kept in different sources. As a result, it becomes hard to access when required. Moreover, when departments have unequal data, tasks on the production line may be postponed and other mistakes made in performance.

Solution: Data consistency and integration

An industrial data management system gives an enterprise a single verified version of information in one space. Real-time data streaming synchronizes the data and gives access to it on the spot.

Challenge II: Human Factor in Handling and Operating Data

Manual data collection requires a switch to an automated system. This method of work slows down the production process. Searching for a person in charge of the necessary data takes time. It leads to further downtime, a fall in productivity, and other bottlenecks.

Solution: Data control

Keeping actual data in DMS gives data access to all the stakeholders. It eliminates bottlenecks and improves focus on more significant tasks and priorities.

Challenge III: Useless Data

With the constant growth of sensors, automated manufacturing systems, applications, and so on, millions of megabytes of produced data are stored at low quality. Not all of this data is essential, and in some situations, information is mixed and duplicated.

As a result, enterprises do not realize the full potential of the data.

Solution: Data quality

Thanks to industrial data management system tools, data is processed, analyzed, and sorted. Therefore, personnel only handle clean data in full.

Challenge IV: Data Leak Risks

Data privacy and security issues have an important place in every company. Corporate data is the value that the enterprise has stored up over an extended period of time, after analyzing, processing, and saving research results.

Data leaks may lead to catastrophic financial losses and serious failures in production.

Solution: Data security

An industrial data management system secures the data with new cutting-edge technologies, protecting it from any threat.

Effective automated data management is the policy that the industry needs. With the help of a data management system, companies will overcome the challenges and undercut the market competition. Industrial data management systems are the solution for high productivity and good company revenue.

The leaders of any industrial company dream of high productivity and profits. Digitizing, processing, and analyzing data quality raises the enterprise to a higher level of productivity. Moreover, it provides more agility to solve operational problems and improve personnel efficiency.

Industrial Data Management Systems: Importance and Key Features

Why Is It Important to Use Industrial Data Management Systems?

As we have already mentioned, every active industrial company produces an immense amount of data, which is poorly operated in most cases.

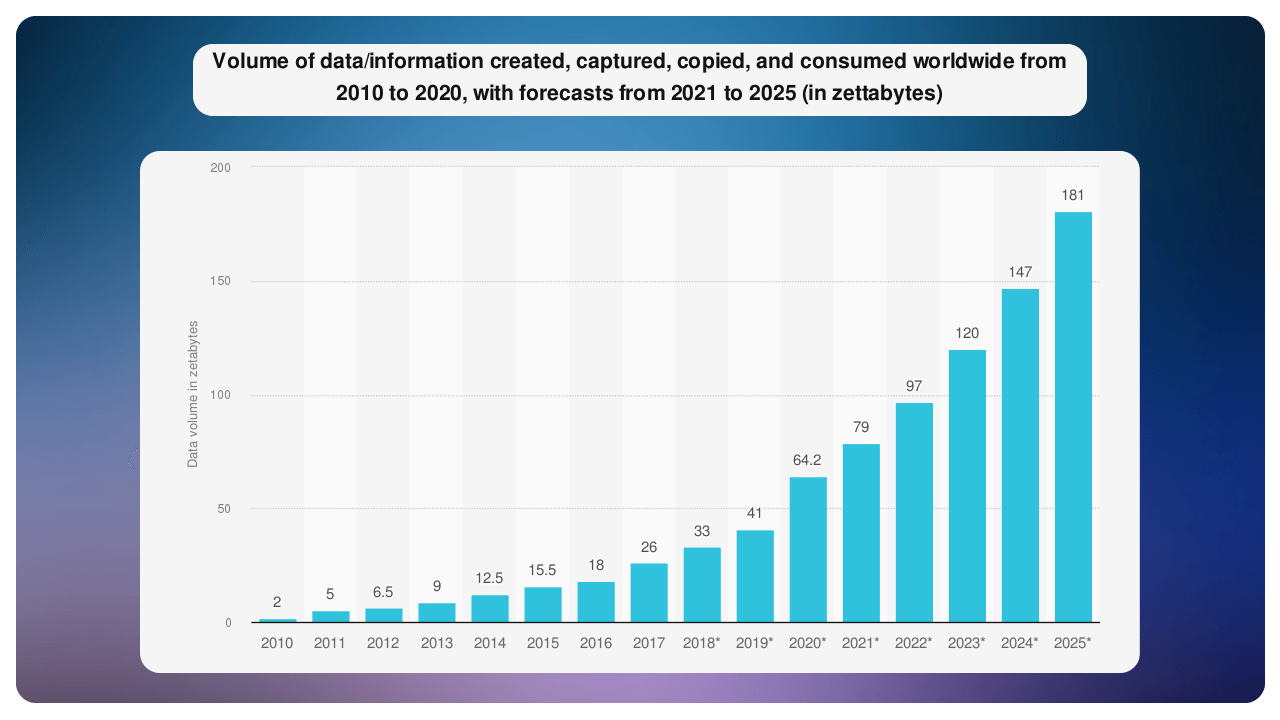

The statistics suggest that the total amount of data produced worldwide will grow considerably. In 2020, the amount of data already reached 64.2 zettabytes. By 2025, that number is predicted to rise to more than 180 zettabytes, according to one study.

It is impossible to stop the manufacturing processes to sort out the data adequately. Therefore, most enterprises face the same big problem: a huge part of raw data is stored in data silos.

Data silos show the companies a fragmented picture of the enterprise’s status because the repository is poorly operated, with outdated and duplicated data controlled by one department isolated from the others.

Data silos lead to various losses, from development strategies to inefficiency in the enterprise’s workflow.

Therefore, an industrial enterprise needs a system of effective tools for data processing that fits its specific requirements. A manufacturer cannot afford his/her company to fall behind the competition, which has already begun to implement digitalization and automation of data processing to run its business more smoothly.

An industrial data management system combines tools that collect, clean, organize, secure, verify and integrate all important data generated by numerous sources, such as:

- in-process test systems;

- rundown tools;

- End of Line test systems;

- data acquisition systems;

- MES or ERP; and many more.

Using data management systems facilitates data management and eliminates data silos. The system has a single clear interface to make handling data simpler for personnel.

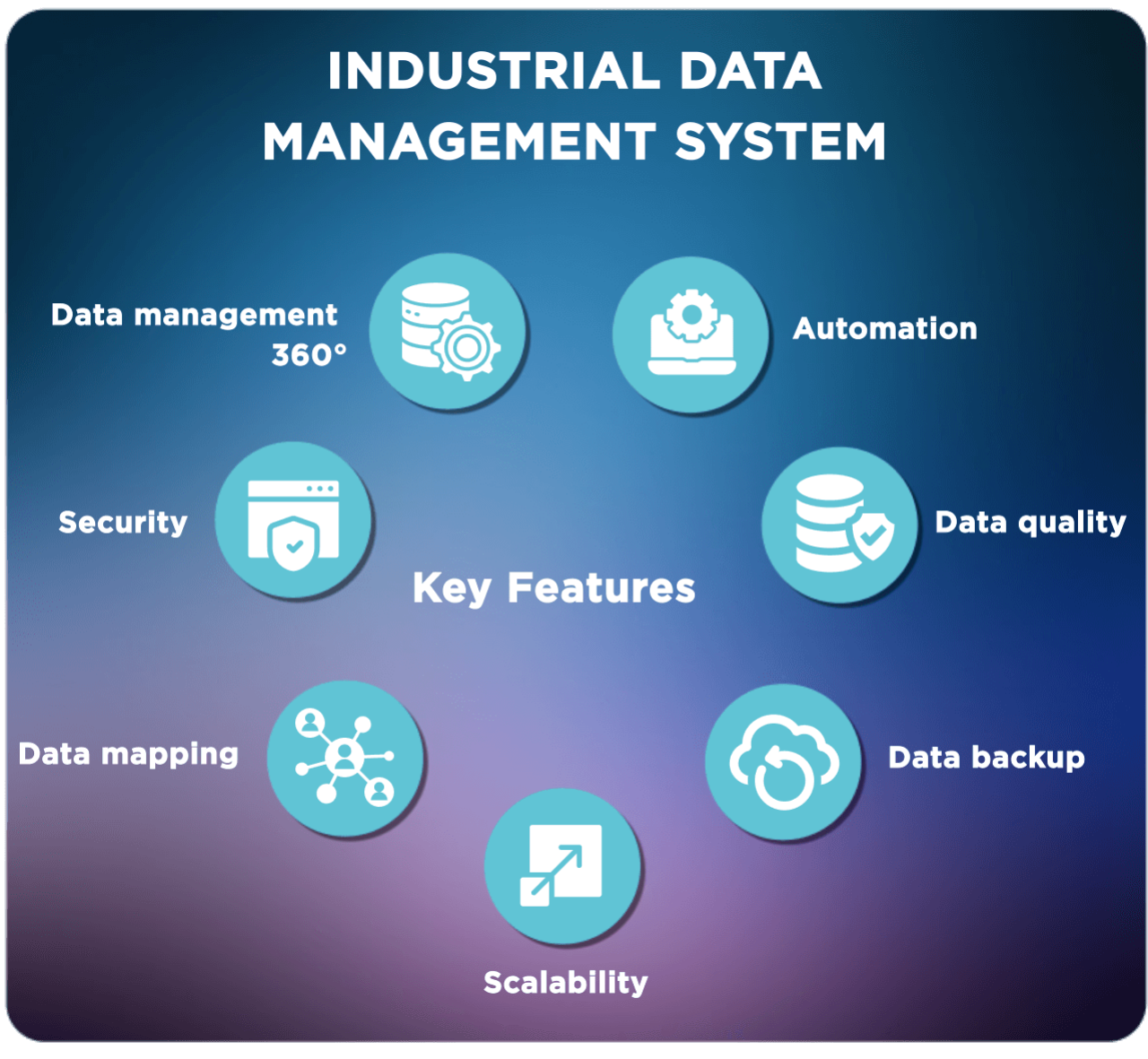

Key Features of Industrial Data Management Systems

An industrial data management system combines tools that collect information from the enterprise’s processes and keep it in a database. To ensure the system works smoothly and brings maximum profit, it should have a set of top features that cover every need of a workflow process at the enterprise.

Understanding the key features will help you choose the best DMS for your own industrial data management software.

1. Data management along the whole operation loop

This feature gives a 360-degree view of the production processes by visualizing in real time and monitoring them from first to last. Moreover, this feature will enable you to control other flows, verify error alerts in time and inspect other systems outside the data management platform.

2. Automation

Automation is another important idea in the industrial data management system. This feature accelerates the system and all processes, saving considerable time. Another benefit of automation is error shortening and quickly bringing the required data to the addressee. This makes your business more agile, profitable, and attractive to investors.

3. Security

Internal data is constantly under threat from leaks, errors, and failures. Therefore, it is a high priority to protect this gold mine of information using modern technologies.

An industrial data management platform contains the latest security tools, including:

- user identification;

- passwords and secrets;

- external communication;

- scratch files;

- backend database; and so on.

You will be confident in your data security policies and the safety of your data.

4. Data quality

Low-quality data creates problems for industrial data management. This is a precise field where misunderstandings, such as manual data entering, data duplication, and inaccurate information, lead to bad decision-making and fatalities.

A data management system allows you to implement your own data handling rules and workflow to achieve the required data quality. This advantage rebuilds the whole operation process and boosts productivity.

5. Data mapping

An essential feature of data management software is data mapping. This sorts data according to the projects in progress. For example, deployed, warehousing, data migration, and many more. Data mapping is the procedure of matching data fields between a target data set and a source. This feature coordinates management processes and maintains high-quality data.

6. Data backup

The possibility of recovering the data plays an important role in the life cycle of an industrial company. Therefore, data backup is embedded into the industrial data management system to prevent data loss risks. As such, this is another security feature.

7. Scalability

With an enterprise’s successful growth, there is a demand to broaden the data management system’s options.

A good data management system is scalable and adaptive to the company’s growth. With the help of the platform, it should be possible to increase the number of users and the variety of production lines.

In today’s highly competitive manufacturing world, an enterprise that stays with the status quo suffers a loss of business. Implementing a data management system is the solution to keep up with the competition.

The Four Best Data Management Software Solutions in 2022

An industrial enterprise’s first action to reduce the dysfunctionality in processing and handling data is to start implementing a data management system. We analyzed the statistics and found the most relevant ready-made database software solutions.

Here are the top four most popular data management systems in 2022, with their pros and cons.

Oracle Database

Oracle is the market leader in the niche of data management systems in collecting, processing and saving data. An Oracle database offers rapid storage and recovery of data.

Pros:

- easy to use;

- different editions for various businesses;

- high level of performance;

- cross-platform database;

- user-friendly apps on different platforms; and

- very fast operations.

Cons:

- difficult to understand the permission scheme;

- expensive license; and

- difficult to get to the right team of technical support.

MySQL

This is an open-source relational database management system with Oracle Corporation support. This database stores data in separate tables instead of using a storeroom, which saves time.

Pros:

- easy to use;

- free;

- possible to cut source code according to requirements; and

- solid data security.

Cons:

- ineffective in managing large databases;

- does not support large database files;

- no developing and debugging tools, unlike in paid databases; and

- no high efficiency in handling transactions, which leads to data damage.

Microsoft SQL Server

This Microsoft relational database management system also aims at data processing and storing. Along with the popular databases above, this one has its own benefits and limitations. Microsoft SQL Server has various supported editions.

Pros:

- multiple applications support;

- editions for different businesses;

- simple to install and use;

- high-level documentation and technical support;

- possible to use both on-premises and in the cloud; and

- useful embedded tools and applications.

Cons:

- expensive Enterprise edition; and

- rapidly changing and difficult to understand licensing.

Amazon RDS

The system helps to operate huge workloads in one database in the cloud. Amazon RDS works well with other databases such as Oracle, My SQL, and Microsoft SQL Server. One of the biggest advantages of Amazon RDS is that the client pays only for the resources being used.

Pros:

- the best security thanks to inbuilt data backup and recovery feature;

- easy databases deployment;

- integrates with other data management systems; and

- quick performance.

Cons:

- low scalability; and

- no possibility to find out the logs because there is no access to the physical server.

A ready-made data management system is a good start in data systematization. It requires time and effort to implement a new scheme into the workflow with minimum interference to the production line.

Some companies deal with the implementation of new data management software issues on their own. But what if a company’s workload is large and the processes need permanent attention?

Therefore, this is the choice: either start using a ready-made data management system or build a unique industrial data management system with the help of an outsourcing software development company.

Both options are acceptable. Your decision depends on the manufacturing enterprise’s goals, resources, size, and budget.

Buying a ready-made data management platform is:

- cheaper; but

- it takes a lot of time, and the company’s human resources; and

- there are possible struggles with missing features, technical support, coding and so on.

Building a custom industrial data management system is:

- more expensive; but

- more reliable and profitable;

- it is developed according to the company’s needs; and

- personal maintenance and coding for scalability, and so on.

We provide more information about the choice between ready-made and custom software in our article.

How Long Does It Take to Build and Implement a DMS System?

Before developing a custom industrial data management system, it is important to understand all the details and steps for implementing the system into the workflow.

The length of the enterprise’s data management system development period and its further implementation depends on:

- current data management maturity level;

- the types and number of data sources;

- the number of employees and their readiness for significant changes;

- the goals and expectations of the company;

- the timelines and urgency; and

- production sphere and budget.

Enterprise Industrial Data Management System Implementation Timeframes

According to VironIT, the development and implementation periods of a new data management system may take:

- 5–12 months for micro and small-sized enterprises (less than 50 employees);

- 12–24 months for medium-sized enterprises (less than 250 employees); and

- 24–36 months for large enterprises (more than 250 employees).

However, all timescales and prices are calculated individually after discovering the needs and goals of the company. You can contact us right now to get a calculation as soon as possible.

Developing and implementing an industrial data management system involves a five-step strategy. These steps will help you understand the whole procedure.

I. Identify your data goals

Your current problem should reflect the data management strategy. What challenges do you want to overcome by implementing the data management system? These may include:

- fixing a production process;

- a better control of specific risks;

- developing an innovative product;

- developing a faster task delivery; or

- cutting operational costs.

II. Define data processes

Once these goals have been identified, it is necessary to determine what processes should be implemented for data handling. For example:

- How and when will the data be collected?

- How and where will the data be packed, stored, and maintained?

- Who will use the data, and for what purpose?

III. Specify your organizational model

Next, you must define how your staff will cooperate in a new data management. The main question is, what kind of operating model is yours: centralized, decentralized, or hybrid? The main points that cover relevant operation models are:

- a single data management owner responsible for data governance;

- stewardship;

- metadata management;

- data quality;

- master data management;

- data architecture; or

- distribution of responsibilities across business lines and IT teams.

IV. Search for an experienced outsourcing software developing company

Then you will want to discuss all your needs and insights with the project manager to guarantee the best results. You should identify employees that work with data now and involve them early in changes with the developing team.

At VironIT, highly-skilled project managers, developers, system analysts, solution architects, and data engineers will build your custom industrial data management system from scratch and help you to implement it step by step.

V. Train your stakeholders

Make sure your personnel is ready for the changes. Provide qualified step-type education and training for all employees concerned.

Implementing a data management system transitions your enterprise to a more convenient, flexible, and agile production method. The strategy above provides you with a painless switchover for efficiency, higher productivity, and income growth.

Conclusion

An industrial data management system is the key to a manufacturing enterprise’s success. Efficient handling of data saves time, releasing energies for opening up new economic challenges and opportunities.

The highly-skilled VironIT team is experienced in development and welcomes cooperation and negotiation. Write to us with your ideas and get all the possible options for your manufacturing enterprise.

(4 votes, average: 4.00 out of 5)

(4 votes, average: 4.00 out of 5)

Comments are closed.